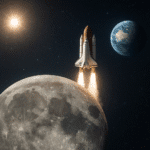

Rocket travel has captivated scientists and dreamers alike, pushing the boundaries of engineering and physics to explore beyond Earth’s atmosphere. This article delves into the core scientific concepts behind modern rocket propulsion, examining the physical laws, chemical reactions, and design strategies that enable spacecraft to surge through space.

Fundamental Principles of Rocket Motion

The science of rocket propulsion relies on Newton’s laws of motion, particularly his third law: for every action, there is an equal and opposite reaction. When a rocket engine expels high-speed exhaust gases downward, an upward thrust force propels the vehicle skyward. When a rocket engine forces hot gas out at high velocity, the combustion process inside the chamber releases energy that accelerates these gases.

The Tsiolkovsky rocket equation, also known as the ideal rocket equation, relates the change in velocity of the rocket (delta-v) to its initial mass, final mass, and the effective exhaust velocity. Engineers use this formula to calculate how much propellant is required to achieve orbit or embark on interplanetary missions.

- Newton’s Third Law: Action and reaction between exhaust gases and rocket body.

- Tsiolkovsky Rocket Equation: Δv = ve ln(m0/mf).

- Delta-v Budget: Allocating velocity increments for gravity losses, drag, and orbital insertion.

Propellants and Combustion Processes

Choosing the right combination of fuel and oxidizer is crucial for optimal performance. The term propellant refers to both the fuel component and the oxidizer needed for combustion. High-performance engines demand propellant pairs with high energy density and manageable storage requirements.

Liquid Propellants

Liquid engines often use kerosene (RP-1), liquid hydrogen, or hypergolic combinations. The cryogenic nature of liquid hydrogen (-253°C) coupled with liquid oxygen yields high specific impulse (ISP) but requires complex insulation systems. Hypergolic propellants ignite spontaneously upon contact, simplifying engine start procedures but posing handling risks.

Solid Propellants

Solid motors contain a pre-mixed grain of fuel and oxidizer cast into the motor casing. These designs offer simplicity and reliability, making them common in military and booster applications. Solid propellants cannot be shut down once ignited, limiting throttle control but providing high thrust-to-weight ratios.

Hybrid Propellants

Hybrid engines combine a solid fuel grain with a liquid or gaseous oxidizer. They strike a balance between the simplicity of solids and the controllability of liquids. Throttling and shutoff capability improve mission flexibility while maintaining a relatively simple architecture.

Nozzle Design and Thermal Management

The nozzle shapes the high-pressure gases expanding from the combustion chamber into a directed jet, converting thermal energy into kinetic energy. A convergent-divergent (De Laval) nozzle accelerates subsonic flow to supersonic speeds past the throat. At the throat, gases reach a Mach number of 1, after which the diverging section further accelerates the exhaust to supersonic velocities, maximizing efficiency.

- Converging Section: Raises gas pressure and temperature before the throat.

- Throat: Narrowest point where flow is choked, achieving Mach 1.

- Diverging Section: Expands gases to supersonic velocities, converting pressure into kinetic energy.

Thermal loads in the chamber and nozzle walls can exceed thousands of degrees Celsius. Cooling systems—such as regenerative cooling where propellant circulates through channels around the chamber—protect structural integrity and maintain performance over long burns.

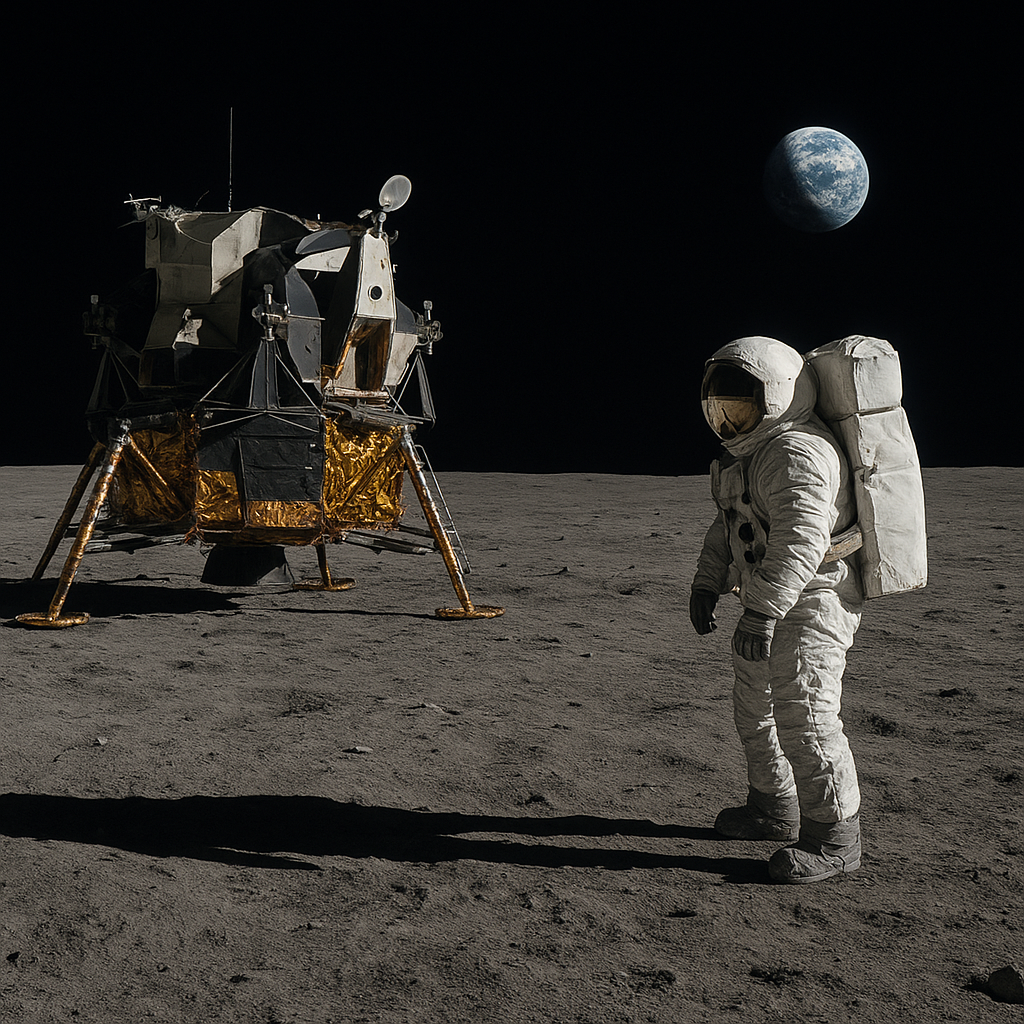

Staging and Mission Profiles

Most orbital rockets use multiple stages to shed dead weight and increase overall delta-v capacity. By dropping empty tanks and engines, subsequent stages start with a higher thrust-to-mass ratio, enabling efficient acceleration into space. Effective staging design balances structural complexity with performance gains.

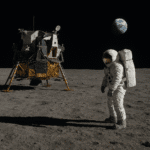

Mission profiles dictate the required delta-v for orbital insertion, interplanetary transfer, or planetary landing. Engineers must plan for gravity losses, atmospheric drag, and trajectory corrections. Profiling every phase ensures that each engine and propellant load contributes optimally to mission objectives.

Emerging Technologies and Future Directions

A new generation of rockets emphasizes reusability and sustainable propulsion. Companies experiment with advanced materials, additive manufacturing, and novel engine cycles to reduce turnaround time and costs. Electric and plasma-based systems, such as ion thrusters, provide high efficiency for deep-space missions, though their low thrust limits their use to in-space propulsion rather than launch vehicles.

Alternative concepts like air-breathing rocket engines and in-situ resource utilization (ISRU) for oxygen and fuel at extraterrestrial sites promise to reshape how humanity explores the solar system. Continuous innovation in propulsion science is unlocking faster travel, higher payloads, and expanded accessibility to the final frontier.