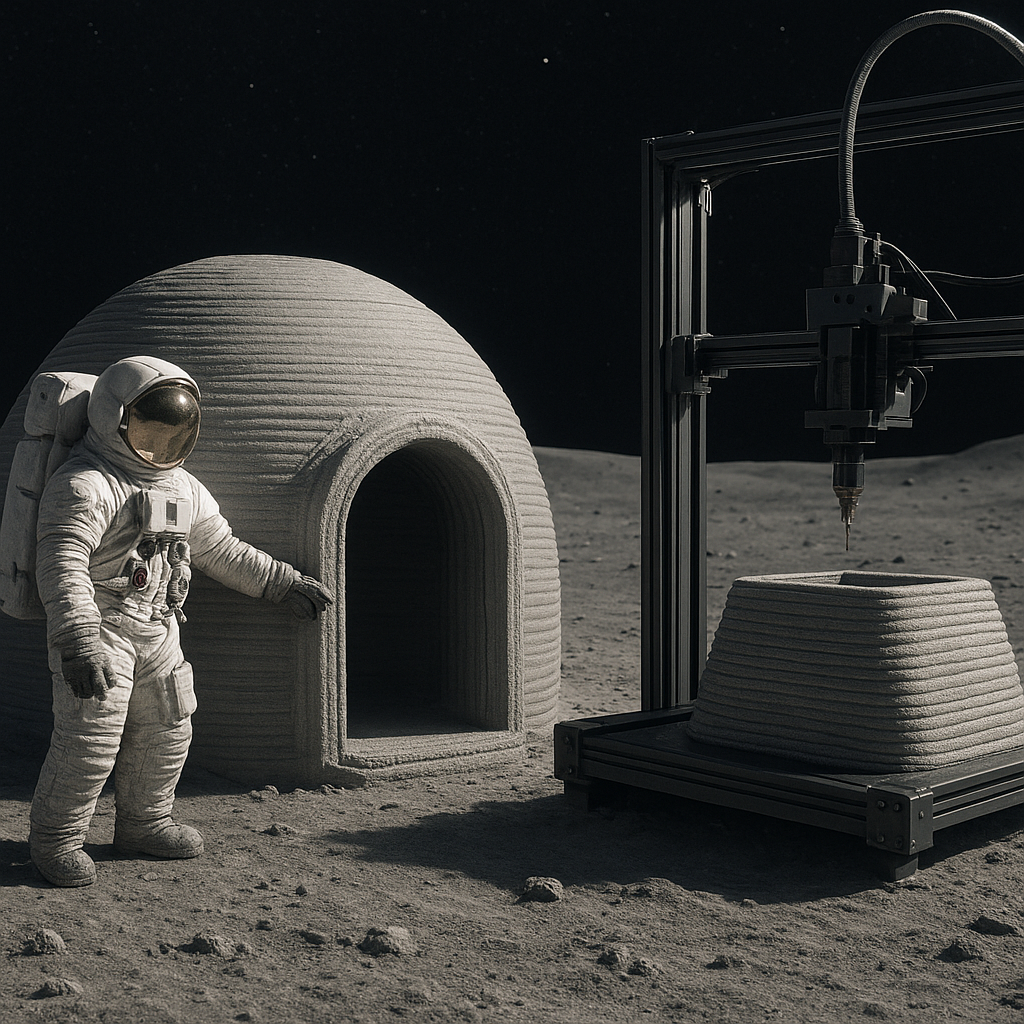

Throughout human history, the dream of building settlements beyond Earth has driven countless technological breakthroughs. Among these innovations, 3D printing stands out as a transformative tool with the potential to revolutionize how we approach off-world construction. By leveraging additive manufacturing techniques, future explorers could bypass many logistical hurdles associated with transporting heavy payloads across millions of miles of space. This article examines the pivotal role of 3D printing in space colonization, exploring the potential of local resources, novel design strategies, and autonomous systems that promise to support the first extraterrestrial communities.

Materials and In-Situ Resource Utilization

One of the most formidable challenges in space colonization is overcoming the high cost and complexity of transporting raw building materials from Earth. Additive manufacturing offers a solution: by employing in-situ resource utilization (ISRU), habitats can be constructed using regolith—a loose form of lunar or Martian soil. Researchers have demonstrated the feasibility of converting regolith into printable feedstock through processes such as sintering, binder jetting, or microwave melting. This approach enhances sustainability by reducing dependency on Earth-based resupply missions.

Key processes under investigation include:

- Binder Jetting: Mixing powdered regolith with a polymer binder produces solid structures after curing.

- Sintering: Applying heat to compacted regolith particles, resulting in rock-like formations.

- Microwave Melting: Targeted microwave energy fuses regolith for fast, energy-efficient building.

Beyond regolith, water ice deposits found near lunar poles and beneath the Martian surface could be exploited as both a construction binder and life-support resource. By integrating water into print formulations, engineers foresee the creation of transparent shielding panels to protect inhabitants from harmful radiation while maintaining clear vistas of the sky. These advancements promise to lower launch costs dramatically and enhance mission flexibility by leveraging locally available feedstocks.

Design and Architecture in Microgravity

Traditional engineering methods often rely on gravity for alignment and support, but in microgravity or reduced-gravity environments, completely new design paradigms emerge. Additive manufacturing enables complex, organic forms that optimize strength-to-weight ratios and offer increased protection against meteorite impacts and cosmic radiation. Architects and engineers collaborate to create habitat modules with curved walls and integrated radiation shielding layers, harnessing the freedom of 3D printing to produce shapes that would be nearly impossible with conventional construction.

Key architectural advantages include:

- Customized Geometry: Tailored designs to maximize internal volume while minimizing material use.

- Multi-Functional Components: Walls embedded with life-support conduits, radiation barriers, and storage compartments printed in a single pass.

- Adaptable Layouts: Modular units that can be seamlessly connected or reconfigured as the colony grows.

Using robotic arms mounted on orbiting platforms or mobile surface units, entire modules can be printed layer by layer without the need for human labor in hazardous conditions. This level of autonomy not only improves safety but also accelerates construction timelines. Future blueprints envision self-healing materials that seal micrometeoroid punctures automatically and transparent domes that provide natural illumination while blocking ultraviolet radiation.

Autonomous Manufacturing and Robotics

Building large-scale infrastructure on the Moon or Mars requires a high degree of self-reliance. To achieve this, space agencies and private companies are developing robotics and AI-controlled systems capable of operating 24/7 with minimal human intervention. Autonomous rovers equipped with extruders can scout locations, analyze soil composition, and begin printing shelters in parallel. These machines rely on advanced sensors, machine learning algorithms, and real-time feedback loops to adjust print parameters based on environmental factors like temperature and dust storms.

Advantages of autonomous manufacturing include:

- Reduced Crew Risk: Robots can construct initial habitats before humans arrive, minimizing exposure to extreme environments.

- Scalability: Multiple robotic units working concurrently can build larger structures in shorter timeframes.

- Fault Tolerance: Self-diagnostic routines and redundant systems ensure continuous operation even when individual components fail.

Early prototypes have demonstrated the ability to print basic geometric shapes, but the next generation of machines aims to fabricate multi-story habitats, airlocks, and landing pads. Integration with orbital resupply missions will allow robots to receive new print heads, binding agents, or electronic components as needed. This approach fosters a resilient supply chain that can adapt to unforeseen challenges and minimize costly abort scenarios.

Future Prospects and Challenges

Looking ahead, the integration of 3D printing into space colonization efforts will shape how humanity expands across the solar system. As technologies mature, printing methods may evolve to include metal sintering for durable mechanical parts, biologically derived materials for life-support systems, and even the 3D printing of food and medical supplies. Collaborative ventures between space agencies, academic institutions, and commercial entities will drive rapid innovations in process efficiency and material science.

However, significant hurdles remain:

- Regulatory Frameworks: Establishing international protocols for resource extraction, environmental protection, and property rights in extraterrestrial territories.

- Energy Supply: Developing reliable, high-power sources—such as small nuclear reactors or solar farms—to meet the demands of large-scale printing operations.

- Human Factors: Ensuring habitat designs address psychological well-being, privacy, and communal living needs for early colonists.

Despite these challenges, the synergy of additive manufacturing and space exploration holds tremendous promise. As prototypes transition into operational systems, the dream of building sustainable, self-sufficient communities beyond Earth moves closer to reality. Harnessing the power of 3D printing to shape our off-world future exemplifies the human drive to innovate and adapt, transforming barren landscapes into thriving, interplanetary homes.