Modern civilization depends on a hidden foundation of rare metals that few people ever see, yet everyone uses every day. From the smartphone in your pocket to satellites orbiting Earth, these materials quietly power the digital age. As demand for cleaner energy and smarter devices grows, so does the strategic importance of rare metals. They are not only vital for economic growth, but also for technological leadership and national security. To understand how supply chains work, which elements matter most, and why recycling is becoming critical, resources such as globalraremetals.info can help reveal the complexity behind this invisible backbone of technology.

What are rare metals?

Rare metals are elements that occur in low concentrations in Earth’s crust, are difficult and expensive to extract, or are produced as by‑products of other mining activities. The term does not necessarily mean they are absolutely scarce; instead, it often refers to their economic and technical rarity.

The most commonly discussed group is the rare earth elements, a family of 17 metals including neodymium, dysprosium, europium, and terbium. In addition to rare earths, other critical rare metals include lithium, cobalt, indium, gallium, platinum group metals, and tantalum. Each of these has unique electronic, magnetic, chemical, or catalytic properties that make them indispensable for modern devices.

Many rare metals do not form rich, concentrated ore deposits. They are scattered in low amounts across large volumes of rock, or they occur as minor components in ores mined for more common metals like copper or aluminum. This makes them more challenging to produce reliably and cheaply, and more exposed to disruptions in mining and processing.

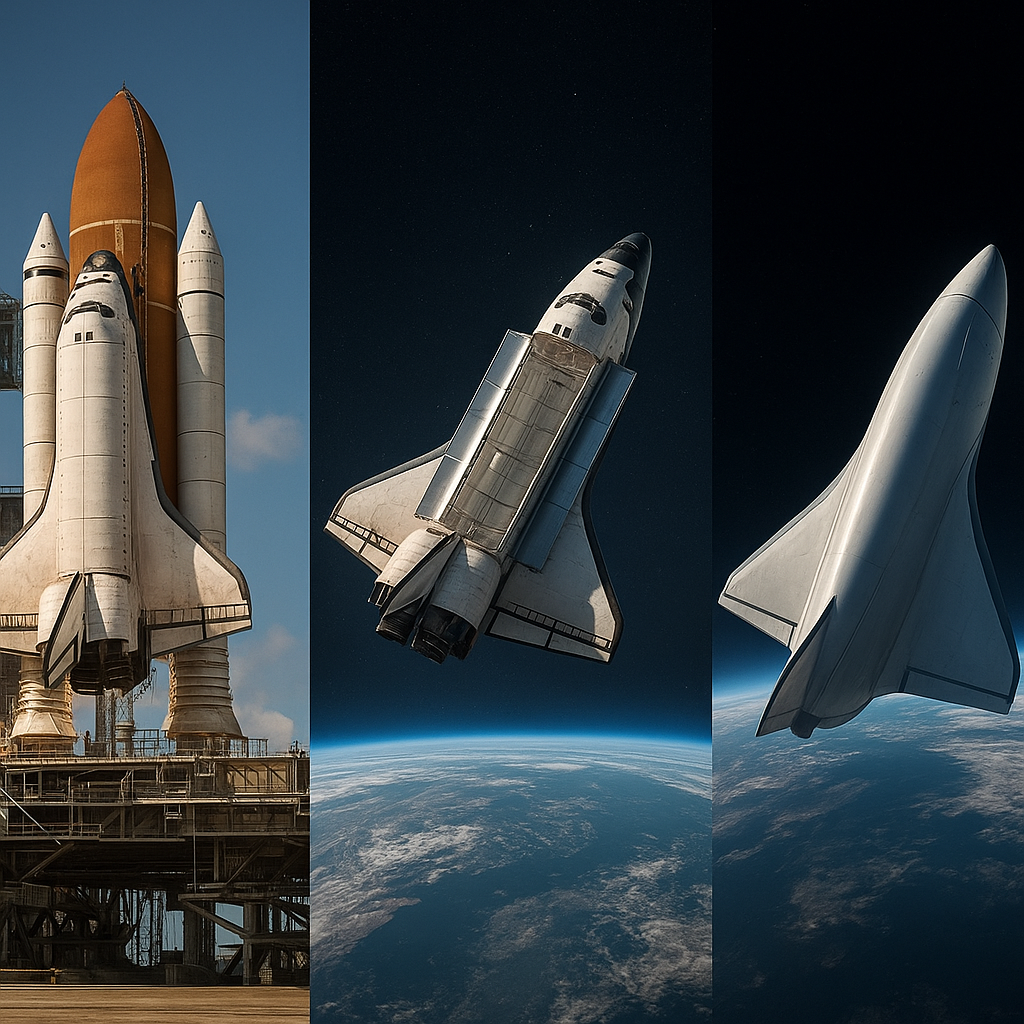

Why modern electronics depend on rare metals

Every advanced electronic device contains a complex mix of rare metals to deliver performance, miniaturization, and energy efficiency. Without them, today’s information and communication systems would be bulkier, slower, and far less capable.

Neodymium and dysprosium are used to make high‑performance permanent magnets in miniature electric motors and speakers found in smartphones, laptops, and headphones. These magnets convert electrical energy into motion and sound with remarkable efficiency, enabling compact designs and long battery life.

Indium is a key component of indium tin oxide, a transparent conducting material deposited on glass or plastic to create touchscreens and flat‑panel displays. Its ability to conduct electricity while remaining transparent is essential for modern user interfaces, from phones to televisions and industrial control panels.

Tantalum is used in tiny capacitors that store and release electrical energy inside circuit boards. Its high capacitance and stability allow engineers to pack far more functions into smaller devices. Without tantalum capacitors, many portable electronics would need to be larger to maintain the same performance.

Gallium, combined with arsenic or nitrogen, forms compounds used in high‑speed semiconductors, LEDs, and laser diodes. These materials power data communications, optical storage, and energy‑efficient lighting solutions that consume far less power than traditional technologies.

Energy transition and green technologies

The global shift towards low‑carbon energy systems is heavily reliant on rare metals. Clean energy technologies often trade fossil fuel consumption for increased material intensity, especially of rare and critical elements.

Permanent magnet motors using rare earth elements power many electric vehicles and wind turbines. Their compact size and high efficiency reduce energy losses and allow engineers to design lighter systems with greater power density. As electric mobility expands, demand for neodymium, praseodymium, and dysprosium is rising rapidly.

Lithium and cobalt are essential for high‑energy rechargeable batteries used in electric cars, grid‑scale storage, laptops, and phones. Lithium‑ion technology has become the dominant solution due to its high energy density and long cycle life, but it also concentrates demand on specific mining regions and processing facilities around the world.

Platinum group metals such as platinum, palladium, and rhodium are vital catalysts in fuel cells and in catalytic converters that reduce harmful emissions from combustion engines. Fuel cells, which convert hydrogen into electricity with water as the only direct by‑product, depend on these metals for efficient and durable operation.

Rare metals are also integral to high‑efficiency solar cells. Elements like indium, gallium, and selenium are used in thin‑film photovoltaic technologies that can be flexible, lightweight, and highly efficient. These advanced solar materials open new possibilities for building‑integrated photovoltaics and portable power systems.

Communication, data, and connectivity

Global connectivity relies on a vast infrastructure of communication networks, data centers, and satellites, all of which depend on rare metals to function reliably and efficiently.

Optical communication systems use rare earth dopants such as erbium in fiber amplifiers to boost signals over long distances without significant loss. This technology underpins long‑haul internet traffic, enabling high‑speed data transfer across continents and under oceans.

High‑frequency and high‑power semiconductor devices based on gallium nitride and related materials make it possible to build compact base stations for mobile networks, including 5G infrastructure. These devices handle high voltages and frequencies while remaining efficient, reducing the size and energy consumption of telecommunication hardware.

Data centers, which host cloud services, search engines, and streaming platforms, rely on rare metals within server processors, memory modules, and cooling systems. Their performance and energy efficiency are tied to advanced materials that provide precise control over electrical and thermal behavior at microscopic scales.

Defense, aerospace, and strategic applications

Rare metals have significant strategic value because they are deeply integrated into defense and aerospace technologies. Many advanced systems cannot function without their specific properties.

Jet engines, rockets, and turbine blades use superalloys containing rare metals such as rhenium and hafnium to maintain strength at extremely high temperatures. These materials enable higher operating temperatures, improving fuel efficiency and thrust.

Guidance systems, radar, and advanced sensors rely on rare earth permanent magnets, special optical materials, and high‑performance semiconductors. These components must function reliably in harsh environments while delivering superior performance, making the choice and quality of materials critical.

Precise navigation, secure communication, and advanced imaging all draw on a combination of rare earth doped lasers, infrared detectors containing elements like indium and antimony, and specialized alloys. As a result, secure access to rare metals supply has become a strategic priority for many nations.

Geopolitics and supply chain concentration

The supply of rare metals is unevenly distributed around the world. A small number of countries dominate the mining and processing of many key elements, leading to concerns about supply security and geopolitical leverage.

Rare earth production is heavily concentrated in a few regions with the technical expertise and industrial infrastructure to process complex ores. Cobalt mining is heavily centered in specific African countries, while lithium extraction is concentrated in particular salt lakes and hard‑rock deposits. This concentration creates vulnerabilities: political instability, trade disputes, or environmental regulations can all cause abrupt disruptions.

Processing capacity is also unevenly distributed. Even when raw ores are mined in one region, they may need to be shipped overseas for refining, separation, and final production of usable compounds. This multi‑stage global chain can complicate transparency and increase the risk of bottlenecks.

In response, many governments are designating certain metals as critical or strategic, launching initiatives to diversify supplies, support domestic processing, and encourage recycling. Companies are redesigning products to reduce dependence on the scarcest elements, but such changes require time, investment, and new technical solutions.

Environmental and social challenges

While rare metals enable more sustainable technologies, their extraction and processing can generate significant environmental and social impacts if not carefully managed.

Mining operations often disturb large areas of land, generate waste rock and tailings, and consume considerable water and energy. Processing rare metals may require acid leaching, high‑temperature furnaces, or organic solvents, which can create pollution and greenhouse gas emissions when poorly controlled.

In some regions, artisanal or poorly regulated mining has led to deforestation, water contamination, and unsafe working conditions. Labor exploitation, including the involvement of children in mining activities, has raised ethical concerns about the origins of certain materials used in consumer electronics and electric vehicles.

Addressing these issues requires stronger environmental regulations, enforcement of labor standards, and greater transparency across entire supply chains. Companies are increasingly expected to audit suppliers, trace materials back to their origins, and adopt certification schemes that promote responsible sourcing.

Recycling and the urban mine

As demand for rare metals grows, recycling end‑of‑life products has become a crucial part of securing future supply. The so‑called urban mine refers to the valuable materials contained in discarded electronics, batteries, catalytic converters, and other products.

Recovering rare metals from waste can reduce the need for new mining, lower environmental impacts, and increase resilience against supply disruptions. Efficient recycling, however, is technically challenging, as many devices contain complex mixtures of materials assembled in tiny components.

Developing better collection systems, standardized product designs, and advanced separation technologies is essential. For example, magnets in wind turbines or hard drives can be removed and processed to recover rare earths. Spent batteries can be treated to reclaim lithium, cobalt, nickel, and other metals for use in new cells.

Designing products with recycling in mind, sometimes called design for circularity, involves choosing materials that are easier to separate, labeling components clearly, and avoiding unnecessary complexity. By considering the full life cycle during design, manufacturers can improve recovery rates and reduce waste.

Innovation and material substitution

Research and innovation are central to reducing pressure on the most critical rare metals while maintaining or improving technological performance. Scientists and engineers are exploring both new materials and new device architectures.

In some cases, substitution is possible. For instance, electric motor designs that rely less on rare earth magnets, or use ferrite alternatives, are being developed for certain applications. Battery chemistries that minimize or eliminate cobalt are also progressing, aiming to reduce dependence on supply‑constrained materials.

At the same time, improvements in material efficiency can lower the amount of rare metals needed per device. More precise manufacturing, thin‑film deposition, and improved magnet design allow engineers to achieve the same or better performance using fewer grams of scarce elements.

Advanced materials such as high‑entropy alloys, new semiconductor compounds, and novel catalysts may eventually offer similar or superior properties without relying on the scarcest elements. This area of research connects materials science, physics, and engineering, and it can reshape future technology roadmaps.

Economic value and technological leadership

Rare metals add disproportionate economic value compared with their physical volume. They often represent a tiny fraction of a product’s mass but are essential for differentiating performance and functionality.

Countries and companies that secure reliable supplies of rare metals and develop advanced processing capabilities gain competitive advantages. They can innovate faster, produce higher‑value goods, and reduce vulnerability to external shocks. This link between resource access and innovation makes rare metals a key factor in technological leadership.

For emerging economies, developing rare metal resources and processing industries can create new value chains and skilled jobs. However, this opportunity comes with responsibilities: ensuring environmental protection, community engagement, and long‑term planning to avoid boom‑and‑bust cycles.

The future of rare metals in technology

As digitalization, electrification, and automation accelerate, the importance of rare metals will continue to grow. Artificial intelligence, advanced robotics, quantum technologies, and next‑generation communication systems all depend on materials with precisely tuned properties at the atomic scale.

Balancing the benefits of these technologies with sustainable resource use will require coordinated efforts across governments, businesses, researchers, and consumers. Policies that encourage recycling, support innovation in materials science, and promote responsible mining are essential to align technological progress with environmental and social goals.

Consumer awareness also plays a role. Understanding that the convenience of a smartphone, an electric car, or high‑speed internet has a material footprint can influence choices about product use, repair, and replacement. Longer product lifetimes, repairable designs, and effective collection systems all contribute to lowering pressure on primary resources.

In the long term, the story of rare metals will be closely tied to how societies manage complexity: balancing strategic interests with environmental limits, embracing circular economy principles, and investing in knowledge. These seemingly obscure elements form a critical bridge between the physical world and the digital systems that increasingly shape human life, making them a cornerstone of modern and future technology.